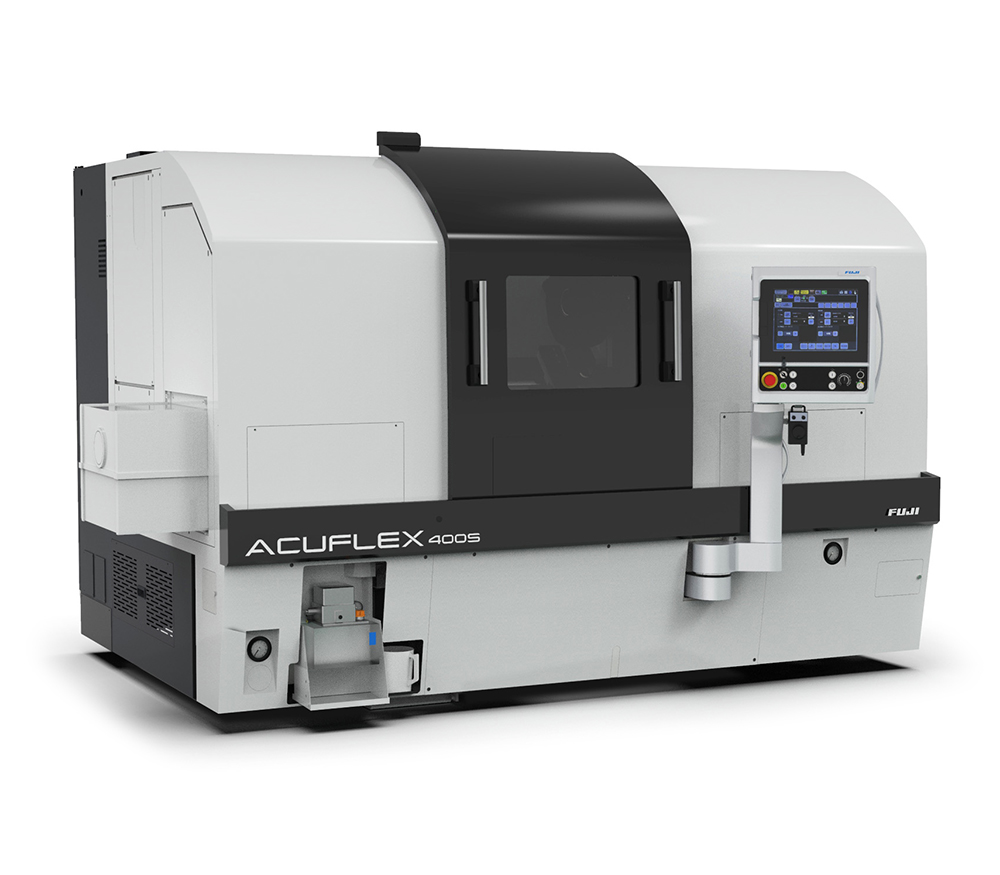

ACUFLEX

Multi Task CNC Lathe ACUFLEX Series

The new ACUFLEX Multi Task CNC Lathe series has slide-ways designed to maintain exceptional rigidity, speed, and accuracy.

- World-class work piece envelope design with high rigidity spindles.

- BMT style live tool holders from various manufacturers can be attached (patent pending).

- High rigidity column

- Anti-vibration steady rest options

- Selectable turrets

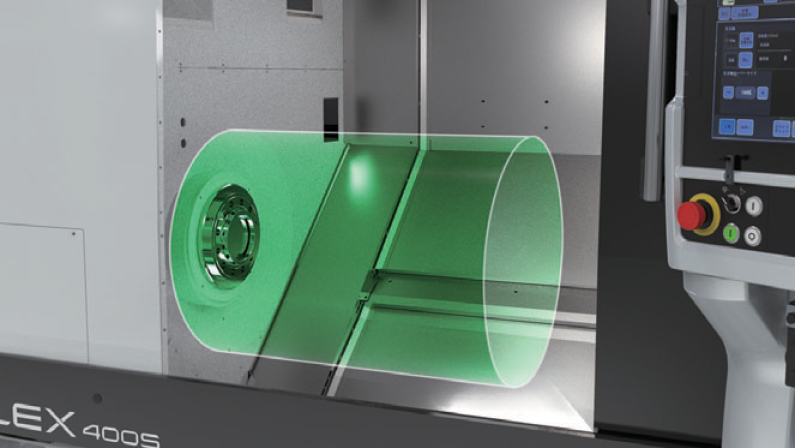

World Class Work Piece Envelope Design

On the left spindle, it's possible to install a 12-inch chuck, taking advantage of the spacious interior of the machine to accomodate sizeable workpieces due to generous swing design.

Swing over bed: ø790

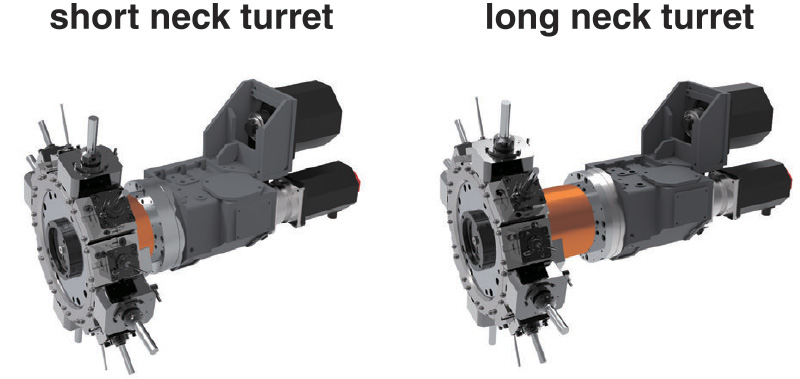

Selectable Turrets

You have the choice between two options: a highly rigid short neck or a long neck design that offers flexibility for right spindle tooling. Additionally, you can choose between a 12-station or 24-station configuration.

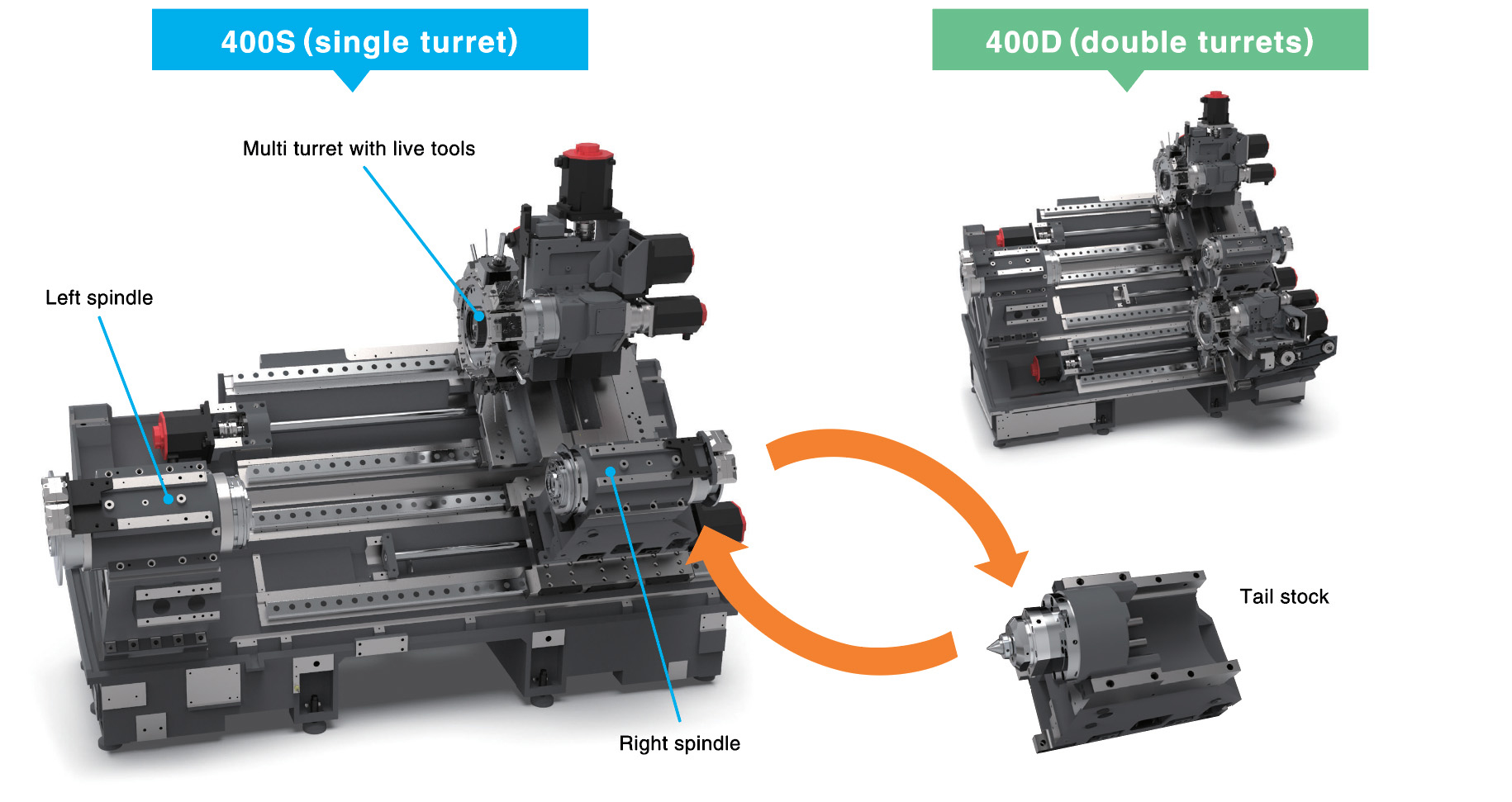

High Rigidity Column

Employing a linear guide featuring a broad mounting pitch accomplishes optimal rigidity and speed for the Z-axis slide. Box way slides are implemented for the XY axis positioned closer to the machining point, facilitating robust cutting capabilities. The right spindle is capable of performing machining operations at a level equivalent to that of the left spindle.

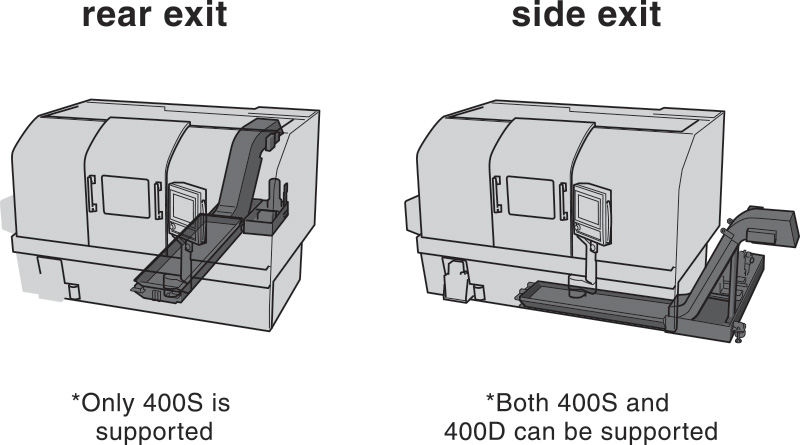

Selecting a Chip Conveyor

You can choose the chip conveyor's discharge direction, either from the right side or the rear, based on the nature of the work and the available space in the factory.

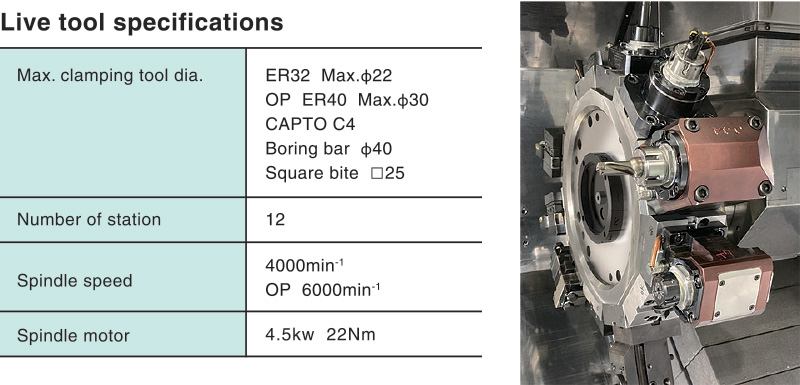

Live Tool

Commercially available BMTs are used. BMT45, BMT55, and BMT60 can be used.